air compressor

High quality, efficiency motor:

The motor be processed and commissioned according to high-level requirements, especially special treatment on the frequency conversion motor and plateau motor , each motor have been strictly tested. The motor is equipped with heavy SKF imported bearings. The two ends of the bearing housings are equipped with grease filler mouth, which is convenient for maintenance, and fully embodies the humanization of the design. Because of the high protection level, the dust and water can be effectively prevented from entering the motor, and the service life of the motor is prolonged.

Unique rational layout:

The machine be designed with electrical integration, it is easy for handling and installation. The inner space of the machine is divided into hot and cold chambers, the internal air circulation is reasonalbe, ensure the sufficient cooling of parts and prolong the service life. In order to reduce the noise of the machine, a fully enclosed removable cabinet has been designed. It contains high quality flame retardant sound insulation sponge, which makes you more flexible in considering the placement of air compressor. Not only in line with environmental protection requirements, but also facilitate the cleaning of the machine.

High efficiency, energy-saving screw type air end:

The host is made of excellent, unique design and precision manufacture. The design of profile optimization reflects the high efficiency and durability, optimization of rotor meshing line maximum, reduce the leakage triangle area, further improve the volumetric efficiency, with a large diameter rotor and the best ratio of length to diameter, ensure the high efficiency and low power output.

Unique bearing arrangement, both ends of the rotor are supported by a fixed radial bearing and a flexible and reliable direct thrust bearing. High quality, large size SKF heavy-duty bearing design, greatly extended the service life. The lip type bearing with slotted inner ring adopts high precise size and quality material, and has the function of pumping and preventing leakage.

Reliable direct drive:

The air compressor with power more than 55kw by elastic coupling and a center bracket and host motor will be combined into one, to ensure in the transportation, installation and operation of the motor and the permanent host, reducing the starting torque, achieve the lowest energy consumption and minimal maintenance workload.

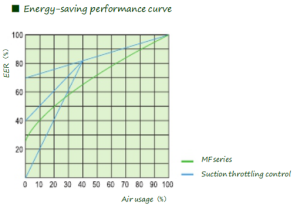

Load / unload control mode to reduce energy consumption

Compared with the previous suction throttling method, the new type of loading and unloading controls has better characteristics without load.

In addition, the suction regulating valve with larger control load adopts special alumina membrane treatment method, and ensures the stable supplyof compressed air and energy saving by switching between loading and unloading.

Performance & Feature

- Improve power & increase exhaust capacity

- Improve air intake filtration to ensure clean air

- Improve inspiratory pressure loss

- Improve exhaust pressure loss

- High quality, efficiency motor

- Reduce the inspiratory temperature

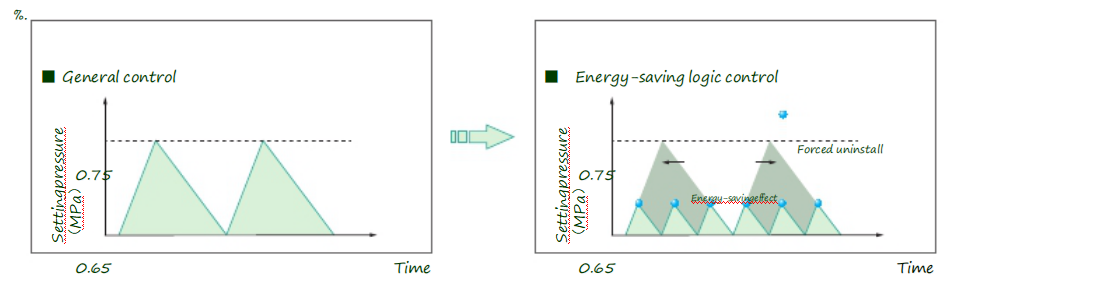

The best control & saving energy

After a certain load time, using the energy saving logic that can be forced to load, to control unnecessary step-up, the maximum energy saving effect of 6

High quality, efficiency motor

The motor be processed and commissioned according to high-level

requirements, especially special treatment on the frequency conversion

motor and plateau motor , each motor have been strictly tested. The motor is

equipped with heavy SKF imported bearings. The two ends of the bearing

housings are equipped with grease filler mouth, which is convenient for

maintenance, and fully embodies the humanization of the design. Because of

the high protection level, the dust and water can be effectively prevented

from entering the motor, and the service life of the motor is prolonged.

Unique rational layout

The machine be designed with electrical integration, it is easy for handling

and installation. The inner space of the machine is divided into hot

and cold chambers, the internal air circulation is reasonalbe, ensure the

sufficient cooling of parts and prolong the service life. In order to reduce

the noise of the machine, a fully enclosed removable cabinet has been

designed. It contains high quality flame retardant sound insulation sponge,

which makes you more flexible in considering the placement of air

compressor. Not only in line with environmental protection requirements, but also facilitate the cleaning of the machine.

High efficiency, energy-saving screw type air end

The host is made of excellent, unique design and precision manufacture.

The design of profile optimization reflects the high efficiency and durability, optimization of rotor meshing line maximum, reduce the leakage triangle area, further improve the volumetric efficiency, with a

large diameter rotor and the best ratio of length to diameter, ensure the

high efficiency and low power output.Unique bearing arrangement,

both ends of the rotor are supported by a fixed radial bearing and a flexible and reliable direct thrust bearing. High quality,

large size SKF heavy-duty bearing design, greatly extended the service life.

The lip type bearing with slotted inner ring adopts high precise size and

quality material, and has the function of pumping and preventing leakage.

Reliable direct drive

The air compressor with power more than 55kw by elastic coupling and

a center bracket and host motor will be combined into one, to ensure in

the transportation, installation and operation of the motor and the

permanent host, reducing the starting torque, achieve the lowest energy

consumption and minimal maintenance workload.

English version control system,

easy to operate, can be

unattended in 24 hours automatic

work.

The main electrical components are

made of German SIEMENS brand,

which greatly improves the service

life of the electric appliance.

The famous brand high performance

motor, IP54 protection, insulation

class F grade, SKF overloaded bearing,

efficiency 3-5% higher than similar

products.

Famous brand air inlet valve,

automatically controls the volume

and reduce operation costs

according to the requirements of the

system gas consumption 0-100%

Efficient overloaded to ensure the

quality of the compressor inlet air

intake filter, to ensure the safety

of the host,which greatly improve

the life of the eQuipment.

Efficint precision gas separation filter

can effectively reduce the oil content

of compressed air in the exhaust and

unit power consumption of the

oil content of only 1-2PPM.

![]()

Spin-mounted oil filter.to completely

filter out the impurities in the

lubricating oil to ensure a clean

lubrication and extend compressor life.

Using the European technology host,

the powerful heart determines the

excellent performance of the whole

machine.

Energy saving AICS

AEOMACHINE air compressor is equipped with the newest control system

design, it integrates the air intake, air evacuation and other functions of the

air compressor.

AICS is equipped with a one-way valve, when the air compressor off or

sudden stop, one-way valve automatically closes to prevent backflow of

compressed air, to avoid the phenomenon of oil well, through air inlet

valve and intelligent control system, pressure sensor control, the compressor

can provide two points’ control (ON / OFF), volume ( 60%-100% ) control

stepless regulation delay auto-shutdown and auto-starting device of 3 kinds

volume of gas, can fully meet the gas requirements for different users.

Eficiency oil gas separation

An efficient oil gas separation system is composed of an inner structure, a

specially designed cylinder, an accumulation type separation core and an oil

return device, the oil content of outlet compressed air is small 2ppm. 1st stage

uses mechanical separation, the oil is separated 99% by a special runner

system.

2nd stage filter material adopts special multi-layer glass fiber filter core, it

makes compressed air quality better.

3rd stage makes the compressed air virtually oil-free by oil return device.

Efficient cooling

Air compressor is designed and manufactured with air-cooled and water-cooled

two cooling methods.

The air-cooled type air compressor adopts a side serrated fin cooler combined

with a suction cooling fan to improve the air circulation condition, and the heat

exchange effect is remarkable. Ensure the cooling of the parts and electrical

equipment in the machine, make the air compressor exhaust temperature

lower, the compression effect is better. Water-cooled air compressor with large

margin of the shell and tube cooler, to ensure the normal operation of the unit

under the poor situation.

Advanced integrated module

The oil filter which is awarded he national patent, is combined with the

temperature control valve to make the connecting pipe more concise in the

machine, avoiding leakage, reducing the pressure loss of the pipeline, low

failure rate, and easy installation and maintenance.

Efficiency air filter

AEOMACHINE configuration is high efficiency, the heavy duty air cleaner used

in machinery and equipment industry by nano coating tech.. The filter is

effectively protected, and the innovative filter media structure can improve the

performance of the filter, and the high-density filter media packing structure

improves the space utilization. High quality filter core can ensure the normal

operation of each part of the system, greatly improve the service life of the

equipment. When filtering, the air flow direction is not changed, and the filter

medium is directly passed through, thereby greatly reducing the pressure loss

and saving energy by 3% compared to the ordinary air filter. The filter

element’s usage life is nearly three times than others similar filters, effectively it

prolongs the service life in the system of oil and gas separator and oil cooling.

Through the repeated tests, the service life near twice times. Efficient filtering

accuracy makes filtering efficiency as 99.9% (1pm).

Multifunctional gas water separator

Post-cooler is assembled with the gas water separator, it saves space and reduces

leakage. Moisture trap adopts advanced separation tech., effectively absorb

the compression volume of condensation water released by air cooler,

when condensate reaches a certain volume, automatic drainage device will

auto discharge water, thereby improving compression air quality. The device

prevent fouling and clogging of condensed water. The gas water separator has the

function of manual drainage, which is convenient for the user to overhaul.

P.S.: The ordinary compressor oil will produce residue (carbon deposition) in the

main engine and oil system, resulting in reduced operating efficiency, frequent

replacement of parts and increased maintenance.

Belt Drive

| Model No. | Power | FAD (m3) | Pre. (MPa) | Size: L×W×H (mm) | Weight(kg) |

| AEO-7.5A | 5.5 kw | 0.85 | 0.7 | 800×720×950 | 240 |

| 0.78 | 0.8 | ||||

| 0.65 | 1.0 | ||||

| 0.55 | 1.2 | ||||

| 0.48 | 1.3 | ||||

| AEO-10A | 7.5 kw | 1.2 | 0.7 | 800×720×950 | 250 |

| 1.1 | 0.8 | ||||

| 0.9 | 1.0 | ||||

| 0.75 | 1.2 | ||||

| 0.65 | 1.3 | ||||

| AEO-15A | 11 kw | 1.65 | 0.7 | 950×800×1160 | 350 |

| 1.5 | 0.8 | ||||

| 1.3 | 1.0 | ||||

| 1.1 | 1.2 | ||||

| 1.0 | 1.3 | ||||

| AEO-20A | 15 kw | 2.5 | 0.7 | 950×800×1160 | 400 |

| 2.3 | 0.8 | ||||

| 2.1 | 1.0 | ||||

| 1.9 | 1.2 | ||||

| 1.7 | 1.3 | ||||

| AEO-25A | 18.5 kw | 3.2 | 0.7 | 1150×900×1380 | 550 |

| 3.0 | 0.8 | ||||

| 2.7 | 1.0 | ||||

| 2.4 | 1.2 | ||||

| 2.1 | 1.3 | ||||

| AEO-30A | 22 kw | 3.8 | 0.7 | 1150×900×1380 | 600 |

| 3.6 | 0.8 | ||||

| 3.2 | 1.0 | ||||

| 2.7 | 1.2 | ||||

| 2.3 | 1.3 |

| Model No. | Power | FAD (m3) | Pre. (MPa) | Size: L×W×H (mm) | Weight(kg) |

| AEO-40A | 30 kw | 5.3 | 0.7 | 1150×900×1380 | 650 |

| 5.0 | 0.8 | ||||

| 4.5 | 1.0 | ||||

| 4.0 | 1.2 | ||||

| 3.6 | 1.3 | ||||

| AEO-50A | 37 kw | 6.8 | 0.7 | 1320×1000×1500 | 800 |

| 6.2 | 0.8 | ||||

| 5.6 | 1.0 | ||||

| 5.0 | 1.2 | ||||

| 4.5 | 1.3 | ||||

| AEO-60A | 45kw | 7.4 | 0.7 | 1320×1000×1500 | 900 |

| 7.0 | 0.8 | ||||

| 6.2 | 1.0 | ||||

| 5.6 | 1.2 | ||||

| 5.0 | 1.3 | ||||

| AEO-75A | 55 kw | 10.0 | 0.7 | 1600×1170×1580 | 1300 |

| 9.2 | 0.8 | ||||

| 8.5 | 1.0 | ||||

| 7.6 | 1.2 | ||||

| 6.9 | 1.3 | ||||

| AEO-100A | 75kw | 13.4 | 0.7 | 1800×1250×1670 | 1500 |

| 12.6 | 0.8 | ||||

| 11.2 | 1.0 | ||||

| 10.0 | 1.2 | ||||

| 9.1 | 1.3 | ||||

| AEO-120A | 90kw | 16.1 | 0.7 | 1800×1250×1670 | 1700 |

| 15.0 | 0.8 | ||||

| 13.8 | 1.0 | ||||

| 12.6 | 1.2 | ||||

| 11.5 | 1.3 |

Direct Drive

| Model No. | Power | FAD (m3) | Pre. (MPa) | Size: L×W×H (mm) | Weight(kg) |

| AEO-20A | 15 kw | 2.5 | 0.7 | 1200×750×1020 | 420 |

| 2.3 | 0.8 | ||||

| AEO-25A | 18.5 kw | 3.2 | 0.7 | 1138×850×1170 | 550 |

| 3.0 | 0.8 | ||||

| AEO-30A | 3.9 | 0.5 | |||

| 22 kw | 3.8 | 0.7 | 1380×850×1170 | 600 | |

| 3.6 | 0.8 | ||||

| 3.2 | 1.0 | ||||

| 2.8 | 1.2 | ||||

| AEO-40A | 5.5 | 0.5 | 1380×850×1170 | ||

| 30 kw | 5.3 | 0.7 | 650 | ||

| 5.0 | 0.8 | ||||

| 4.5 | 1.0 | ||||

| AEO-50A | 4.0 | 1.2 | |||

| 6.8 | 0.5 | 1500×1000×1320 | 850 | ||

| 37 kw | 6.7 | 0.7 | |||

| 6.2 | 0.8 | ||||

| 5.6 | 1.0 | ||||

| 4.9 | 1.2 | ||||

| AEO-60A | 7.6 | 0.5 | 1500×1000×1320 | 900 | |

| 45kw | 7.4 | 0.7 | |||

| 7.0 | 0.8 | ||||

| 6.2 | 1.0 | ||||

| 5.6 | 1.2 | ||||

| AEO-75A | 10.2 | 0.5 | 1900×1250×1600 | 1700 | |

| 55 kw | 10.0 | 0.7 | |||

| 9.6 | 0.8 | ||||

| 8.5 | 1.0 | ||||

| 7.6 | 1.2 | ||||

| AEO-100A | 14.0 | 0.4 | 2000×1250×1670 | 1850 | |

| 13.5 | 0.5 | ||||

| 75 kw | 13.4 | 0.8 | |||

| 12.6 | 0.8 | ||||

| 11.2 | 1.0 | ||||

| 10.0 | 1.2 | ||||

| AEO-120A | 16.8 | 0.4 | 2000×1250×1670 | 1950 | |

| 16.5 | 0.5 | ||||

| 90 kw | 16.2 | 0.7 | |||

| 15.0 | 0.8 | ||||

| 13.8 | 1.0 | ||||

| 12.3 | 1.2 | ||||

| AEO-150A | 75 kw | 21.6 | 0.4 | 2700×1470×1840 | 2700 |

| 90 kw | 21.3 | 0.5 | |||

| 110 kw | 21.0 | 0.7 | |||

| 19.8 | 0.8 | ||||

| 17.4 | 1.0 | ||||

| 14.8 | 1.2 |

| Model No. | Power | FAD (m3) | Pre. (MPa) | Size: L×W×H (mm) | Weight(kg) |

| AEO-175A | 90 kw | 25.2 | 0.4 | 2700×1470×1840 | 2900 |

| 110 kw | 24.8 | 0.5 | |||

| 132 kw | 24.5 | 0.7 | |||

| 23.2 | 0.8 | ||||

| 20.5 | 1.0 | ||||

| 17.4 | 1.2 | ||||

| AEO-200A | 110 kw | 29.6 | 0.4 | 2700×1470×1840 | 3200 |

| 132 kw | 29.2 | 0.5 | |||

| 160 kw | 28.7 | 0.7 | |||

| 27.6 | 0.8 | ||||

| 24.6 | 1.0 | ||||

| 21.5 | 1.2 | ||||

| AEO-250A | 132 kw | 33.5 | 0.4 | 3200×2000×2025 | 3500 |

| 160 kw | 33.0 | 0.5 | |||

| 185 kw | 32.0 | 0.7 | |||

| 30.4 | 0.8 | ||||

| 27.4 | 1.0 | ||||

| 24.8 | 1.2 | ||||

| AEO-300A | 160 kw | 37.0 | 0.4 | 3200×2000×2050 | 4000 |

| 185 kw | 36.5 | 0.5 | |||

| 220 kw | 36.0 | 0.7 | |||

| 34.3 | 0.8 | ||||

| 30.2 | 1.0 | ||||

| 27.7 | 1.2 | ||||

| AEO-350A | 185 kw | 43.5 | 0.4 | 3200×2000×2050 | 4500 |

| 220 kw | 42.8 | 0.5 | |||

| 250 kw | 42.0 | 0.7 | |||

| 40.5 | 0.8 | ||||

| 38.2 | 1.0 | ||||

| 34.5 | 1.2 | ||||

| AEO-430A | 220 kw | 54.0 | 0.4 | 3500×2000×2050 | 6000 |

| 250 kw | 52.5 | 0.5 | |||

| 315 kw | 51.0 | 0.7 | |||

| 50.2 | 0.8 | ||||

| 44.5 | 1.0 | ||||

| 39.5 | 1.2 | ||||

| AEO-480A | 315 kw | 65.0 | 0.5 | 3500×2000×2050 | 6500 |

| 355 kw | 64.0 | 0.7 | |||

| 61.0 | 0.8 | ||||

| 56.5 | 1.0 | ||||

| 49.0 | 1.2 | ||||

| AEO-540A | 400 kw | 71.2 | 0.7 | 3800×2000×2050 | 7200 |

| 68.1 | 0.8 | ||||

| 62.8 | 1.0 | ||||

| 52.2 | 1.2 |

中文

中文 Português

Português